Monitoring system for mixers

Project description

A large food plant producing bakery product (export company), had demand for the mixers monitoring system. This system intended to be a part of the complex product tracking system along the production line.

The operation of the mixer is one of the key points in the product quality. There are many different recipes (hundreds) for the mixer machine.

Due to big number of recipes which are constantly being changed, the HMI panel stores few main recipes, which then operators may modify on demand before mixing cycle.

To further improve control over the mixing process, the enterprise decided to implement a system which would allow:

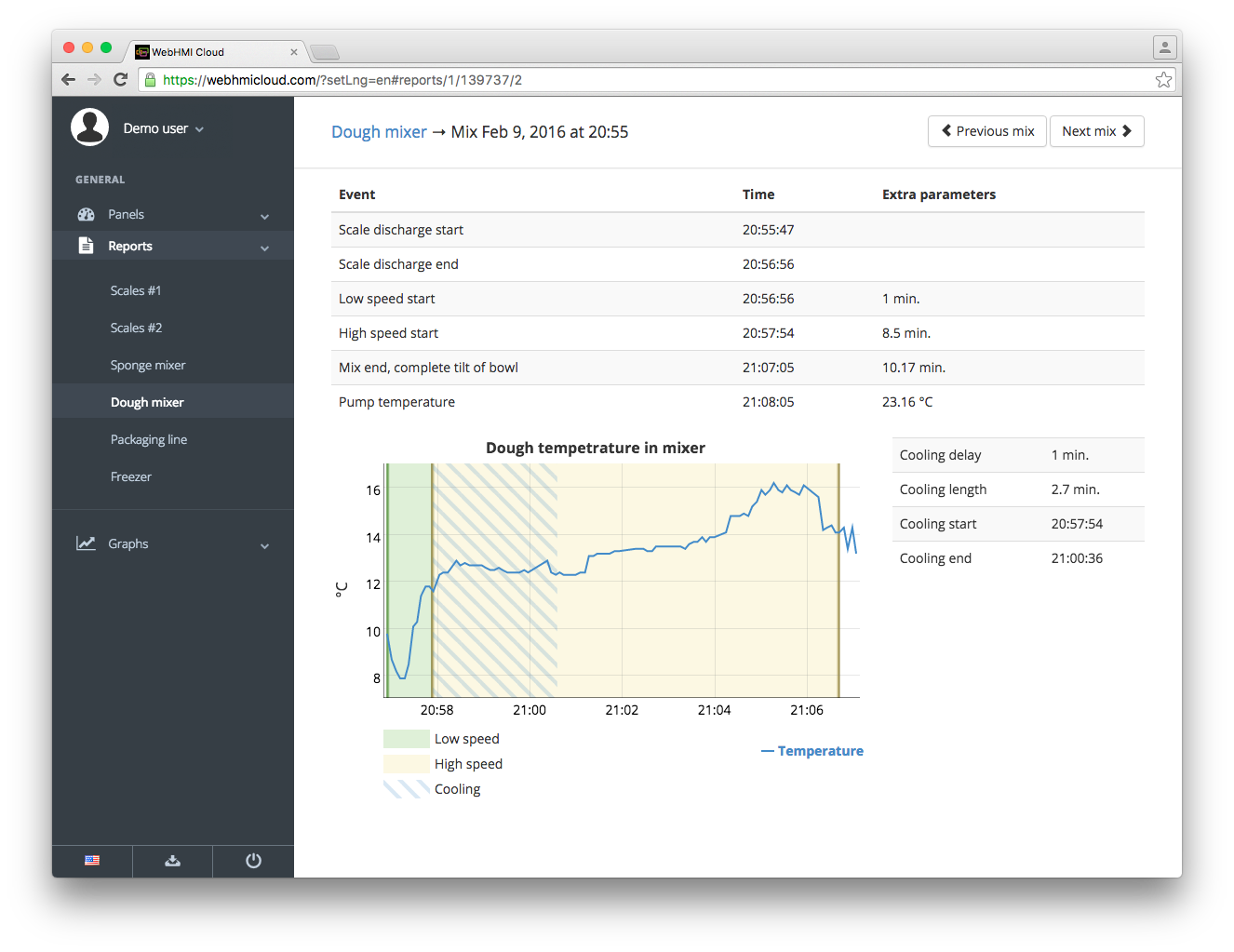

- To log process sequence – start and stop time, moments of turning different speeds on, pauses between process steps (e.g, between mixing stop and discharge etc.), aiming to check operation, check actual recipe (operator input) to set recipe match.

- To record dough cooling process during mixing cycle, to optimize cooling process.

- To record actual dough temperature during discharge, using external temperature sensor. This sensor is installed in the pipe (dough is pumped though the pipe) and connected to panel indicator of TRM series(Owen). The dough starts to self-heat after discharge, so the operator have to carefully watch for the time when sensor temperature changes from air to dough temperature.

- To store data for a long time for the following analysis. Since the product was frozen, stored and sent to customers (mainly abroad ones) after quite long time, in case of customer’s claims the plant had to be able to analyze the source of the problem using logged mixer data.

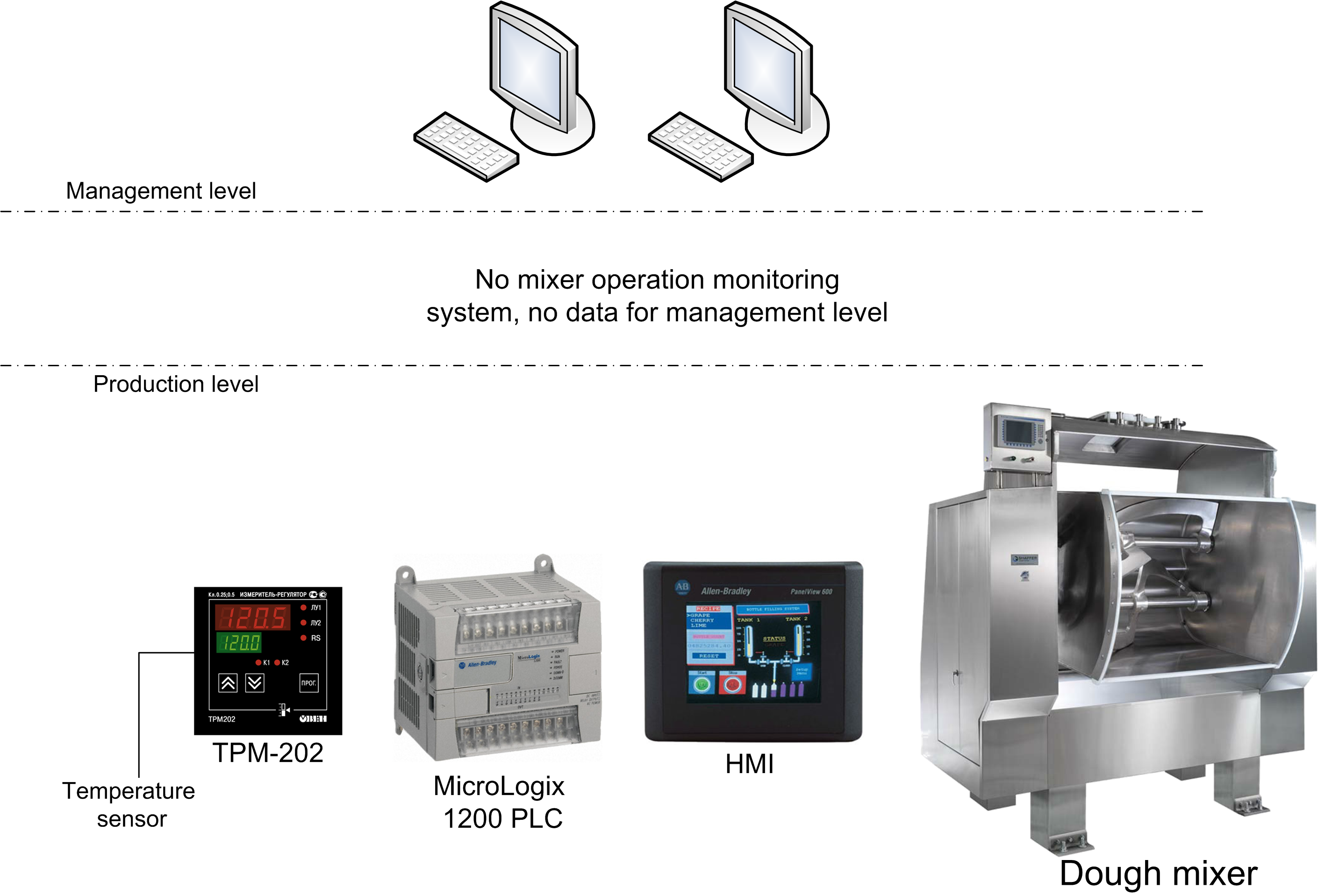

Initial system structure

- Mixer control panel with:

- Rockwell MicroLogix 1200 PLC

- HMI operator panel

- Temperature indicator TRM-202

Existing drawbacks

- The recipes were constantly changed by operators, instead of selecting, and this lead to mistypes. Besides this, operator could also violate process sequence, e.g. by waiting too long before discharging. Without logging system, it were hard to judge if the problems were caused by operator actions.

- The temperature during discharge were very uncertain, depending on when the operator started to watch the sensor. Best method would be to automatically find low temperature minimum point on the temperature graph.

- These are comlicated tasks for the HMI & PLC – interface with graphs, large database (printing and reporting) and programming not supported communication protocol (like TRM-202’s native Owen protocol). At the same time, the plant works in 3 shifts every day, and has only 1-2 days for maintenance, so the tecnical staff just has no time to develop and comission project for such task in running hours. Any downtime is unaccepptable.

So, the demand was for the solution at reasonable price, which would allow to quickly, using configuration mode get an application to log and monitor the mixer machine.

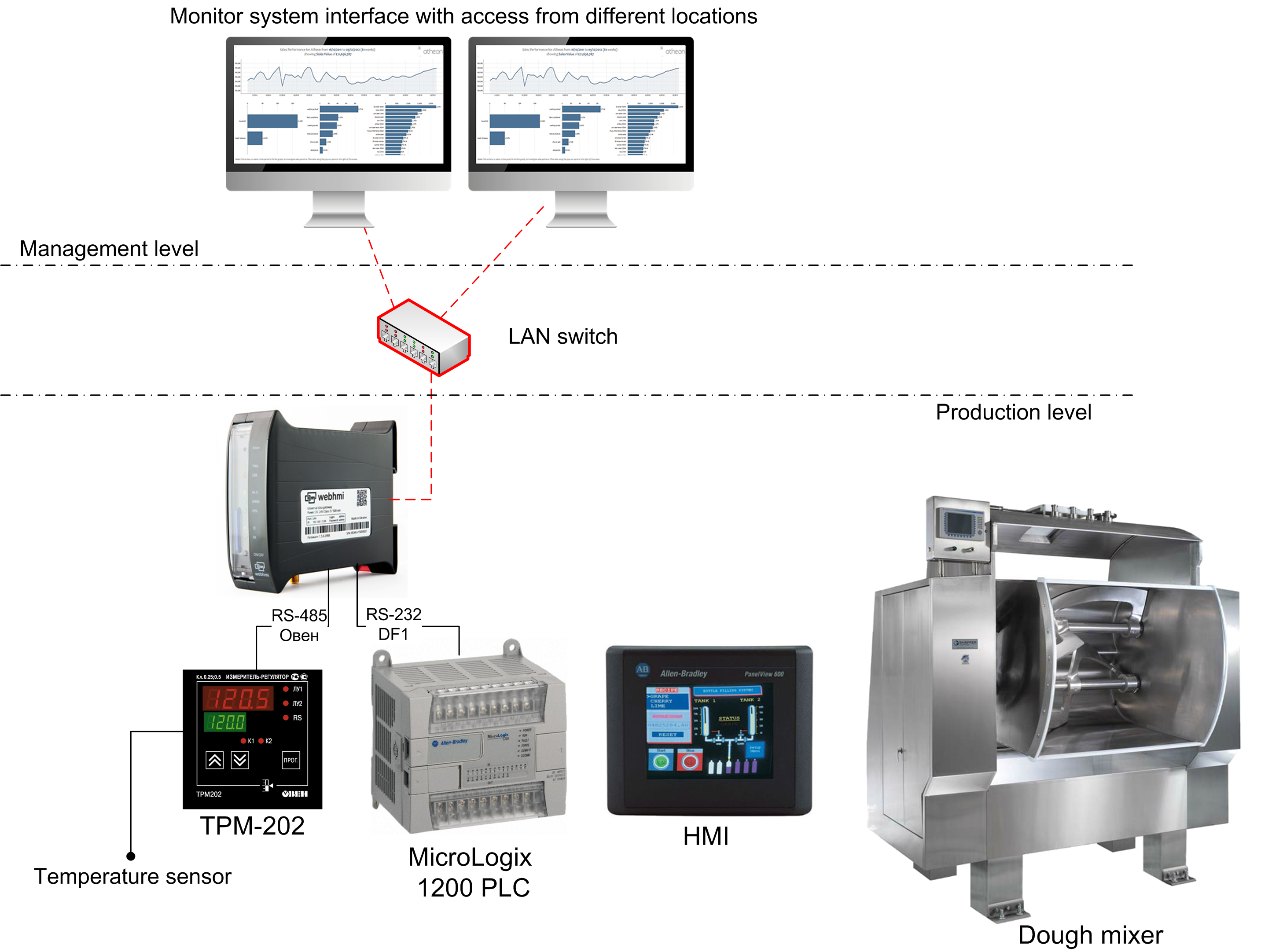

Project implementation with WebHMI

WebHMI’s features leveraged quick and efficient solution of the task:

- PLC was connected using USB/232 converter to serial port with open DF1 protocol.

- TRM-202 was connected via RS-485 with Owen communication protocol

- The reports was configured using WebHMI’s event and scripts mechanisms, not interfering PLC program.

- Data is visualized using web interface – the staff just browse WebHMI on LAN and views or prints the required report for interested date/time. This data can be read from WebHMI by business application (1C, Excel etc.) using API calls.

An example of mixing cycle reprot on cloud server

Advantages

- Fast configuration time, due to WebHMI intrinsic features – wide range of industrual protocols support, scripts and event mechanisms.

- The development were done without interfering mixer PLC operation.

- Встроенные средства визуализации и графики позволили не только разработать интуитивно понятный интерфейс готовой системы, но и были полезным инструментом отладки и аналитки процесса в ходе разработки.

- The reportds can be viewed by different persons, from different locations.

- The system finally made staff more responsible and improved discipline.

- After analysis of the cooling temperature graphs, a better and more efficient cooling mode adjusment were discovered.

Accompanying positive advantages of WebHMI usage were also:

- Ability to remotely program and debug the operation of the PLC control mixer, from the remote workstation of the chief engineer, using the built-in “virtual serial port” function

- The built-in VPN support allowed remote access to the system from the Internet, which made it possible to conveniently view the protocols at any time from any place not only to the bakery’s specialists, but also to the top management of this bakeries network and to transfer the recipe to other bakeries.

- After equipping the unit with the WebHMI integration controller, the mixer assembly is fully ready in the future to include it in the system of integrated monitoring and tracking of the products – from the initial point (kneading the dough) to packing and shipping. Everything you need for this already exists on the WebHMI board – built-in development tools, communication capabilities, scripts, API support, etc.