Monitoring system for batching process

Project description

A large food plant producing bakery product (export company), had demand for the batching system monitoring. This system intended to be a part of the complex product tracking system along the production line.

The scales is a bakery production starting point. With errors during the batch process, the product quality can not be guaranteed. Getting comprehensive report about batching process is a key to determine possible cause of errors and decide on measures to avoid them. The production has a wide range of recipes (hundreds) for batching system.

Due to a big number of recipes which are constantly being changed, the HMI panel stores only few main recipes, which then operators may modify on demand before batching cycle. Usually batching goes in series of repeated cycles of the same recipe, but during each cycle different abnormal situations may happen like water temperature deviation (which should be stable), emergency stops, excessive sediments on the scales etc.

There was a reporting application for batching process, but it was out-dated and very inconvenient in use.

To further improve control over the batching process, improve reports availability the enterprise decided to implement a system which would allow:

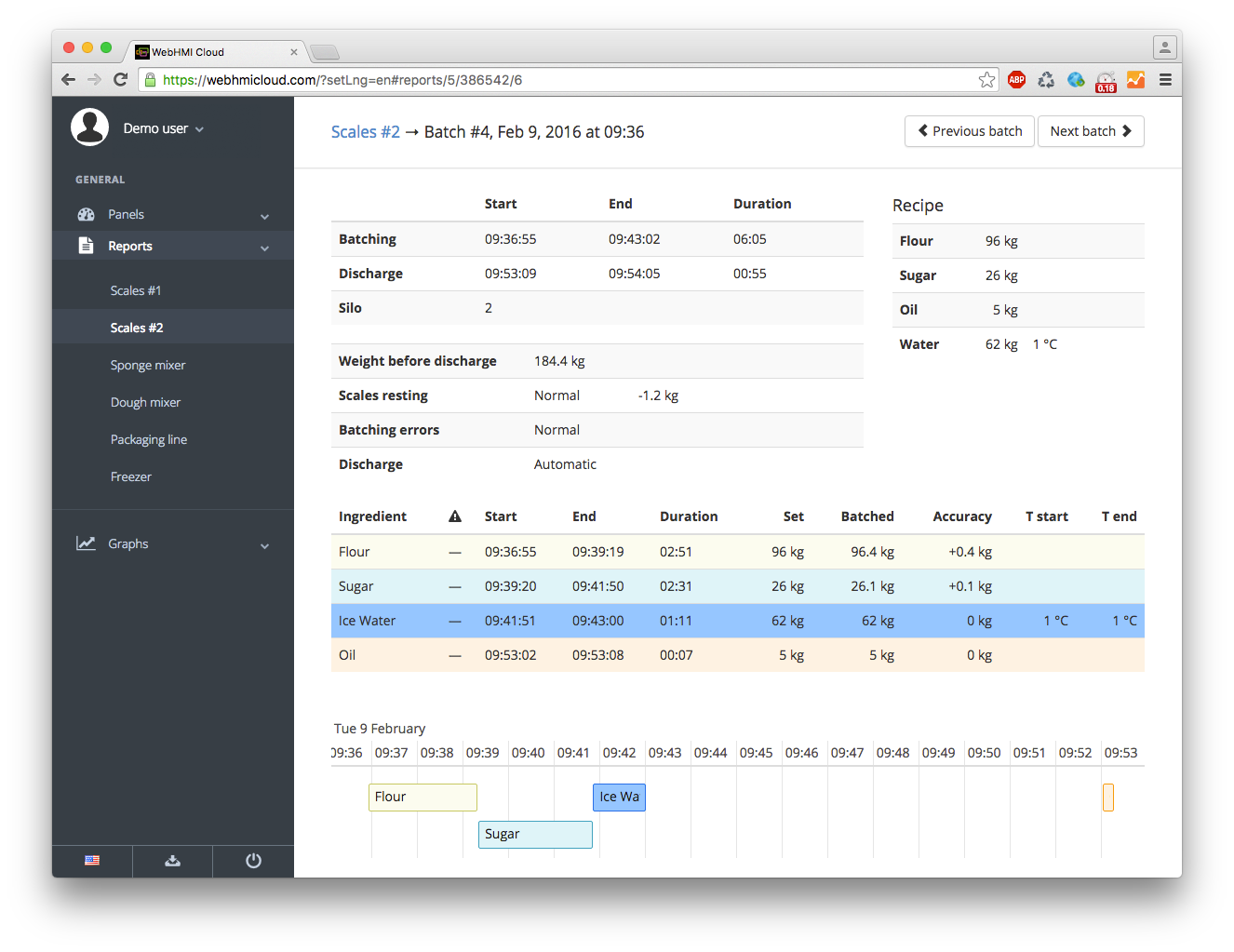

- To generate reports, so that in each batching cycle one can see recipe presets, actual weights of individual ingredients with batching errors, start and stop times of each ingredient batch, delays between cycles and other information.

- Reports should have 2 levels – one list should contain a list of all batches with error/no erros sign, and each entry in the list should go to second level with detailed report .

- To store data for a long time for the following analysis. Since the product was frozen, stored and sent to customers (mainly abroad ones) after quite long time, in case of customer’s claims the plant had to be able to analyze the source of the problem using logged batching data.

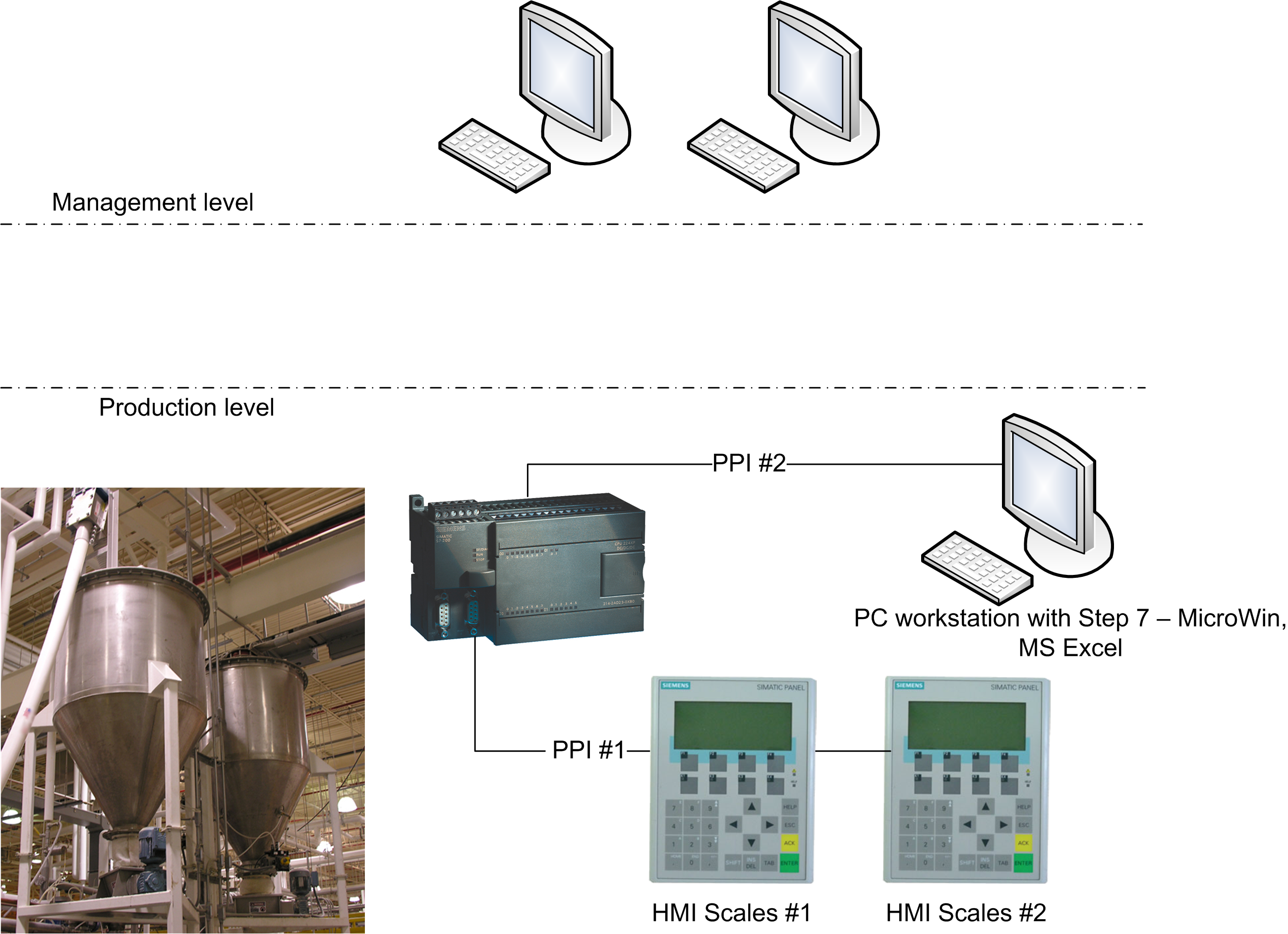

Original system structure

- Bathing system control panel for controlling 2 scales with:

- Siemens S7-200 PLC 1 pcs.

- HMI panel OP-77 2 pcs.

- PC nearby baching control panel with Step 7 – MicroWin software and obsolete version of MS Excel

Existing system drawbacks

- Existing reporting applicaton was implemented using MicroWin’s datalog function – all required signals were recorded with timestamps in PLC memory, then this dump was exproted into *.DAT file, with followed parsing in MS Excel macro.

- This datalog function took all free memory of the PLC, that made difficult to edit PLC program and even caused PLC hangs.

- Manual handling of the files involved in this process was very inconvinient. Macros was for obsolete MS Excel version and just would not work on newer versions. So this required dedicated PC workstation.

- This is a comlicated task – to develop new reporting application with handy view functions, printing, stroring large database etc. At the same time, the plant works in 3 shifts every day, and has only 1-2 days for maintenance, so the tecnical staff just has no time to develop and comission project for such task in running hours. Any downtime is unaccepptable.

So an ideal thing for this project was some task – oriented solution, which would allow not to use low level coding, but to configure PLC polling, recording data, to view, search required batch reportds, and get some extra info like historical graphs, preferrably not depending on OS platform (e.g. in web-browser).

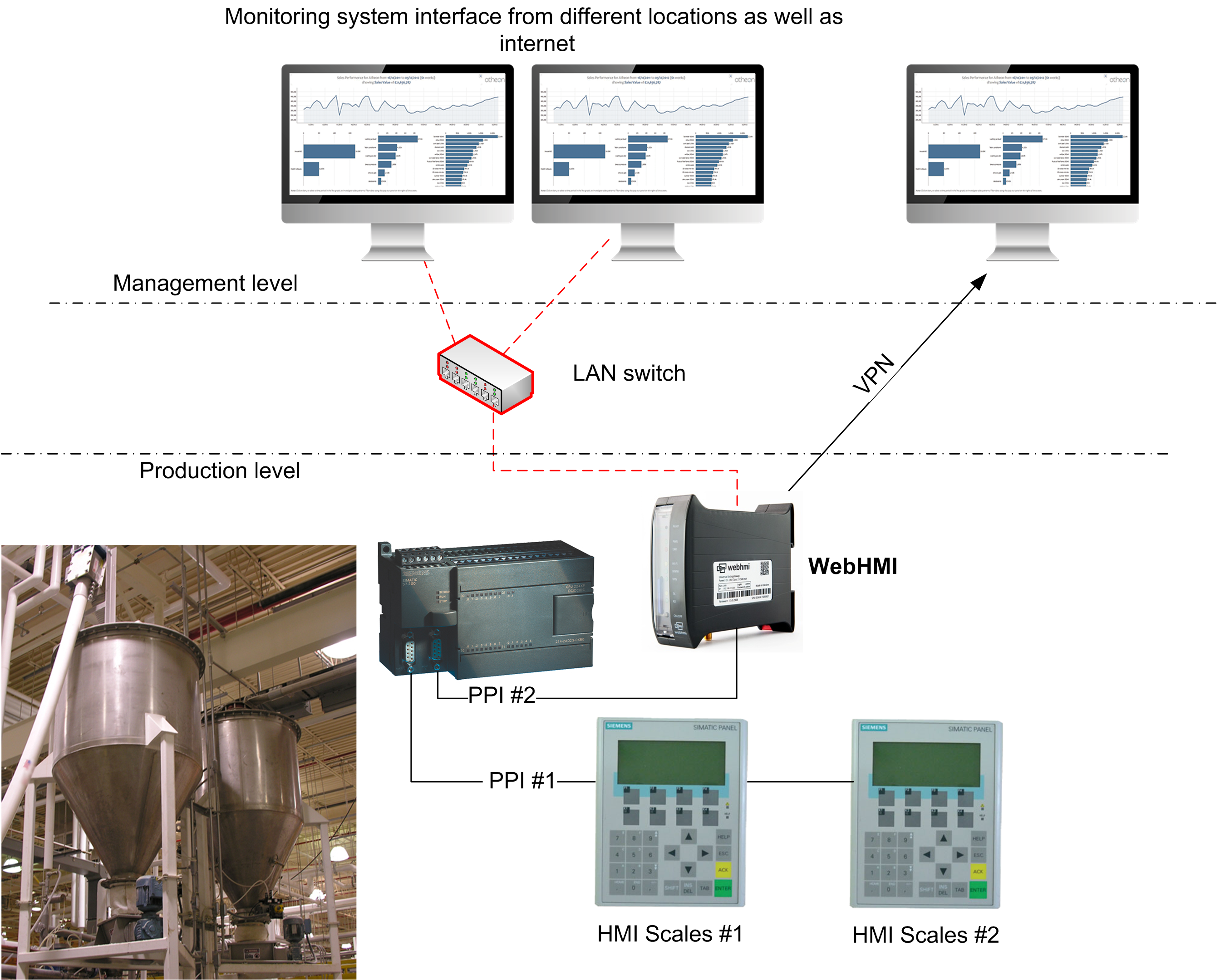

Project setup with WebHMI

Intrinsic features of WebHMI leveraged fast and easy solution for the task of logging and reporting batching system operation.

- S7-200 was connected via RS-485 and PPI communication protocol

- The reports was configured using WebHMI’s event and scripts mechanisms, not interfering PLC program.

- Data is visualized using web interface – the staff just browse WebHMI on LAN and views or prints the required report for interested date/time. This data can be read from WebHMI by business application (1C, Excel etc.) using API calls.

Advantages

- Automatic report generating and options to choose date/time, sorting while viewing the reports.

- Fast configuration time, due to WebHMI intrinsic features – wide range of industrial protocols support, scripts and event mechanisms.

- The development was made not interfering the equipment in operation.

- Not only did the WebHMI’s visualation and graphic tools allowed to develop intuitive interface for the system, but also were useful tools of analytics and debug during implementation.

- The system finally made staff more responsible and improved discipline.

Batching system report example at the cloud level2 server:

Accompanying positive advanteages of WebHMI usage were also:

- Ability to remotely program and debug the operation of the PLC control mixer, from the remote workstation of the chief engineer, using the built-in “virtual serial port” function.

- The built-in VPN support allowed remote access to the system from the Internet, which made it possible to conveniently view the protocols at any time from any place not only to the bakery’s specialists, but also to the top management of this bakeries network and to transfer the recipe to other bakeries.

- After equipping the batching system with the WebHMI integration controller, the batching system is fully ready in the future to include it in the system of integrated monitoring and tracking of the products – from the initial point (kneading the dough) to packing and shipping. Everything you need for this already exists on the WebHMI board – built-in development tools, communication capabilities, scripts, API support, etc.