Technical Specifications

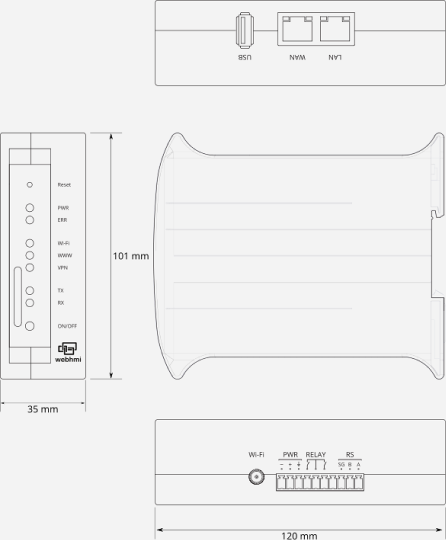

Dimensions

Features and advantages

Direct control and monitoring via the web — in a local network or the Internet, from any platform — mobile phone device, tablet, laptop, computer, etc., simultaneously from different locations, with no limit on the number of users

On-line Development Environment, which is available and ready immediately after the device power on, with no restrictions on the number of tags or licenses for additional software modules.

API to communicate directly with user applications.

Support for popular industrial protocols, with the ability to use different protocols on the same physical line, and to add custom protocols.

The devices can be used for supervisory control of distributed systems when they transmit data to the cloud-based system Level2.

Visualization

Built-in interface editor: built-in editor that runs in a common web browser allows you to create visual screens similar to the screens in HMI or SCADA systems, with elements of text, vector graphics, animation, trends, historical graphs, messages, text entry fields, and elements of recipe control.

Access control: different levels of access can be granted for different users as well as access restrictions to specific dashboards (screens)

Communication with the automation devices

Supported protocols:

- Modbus RTU/ASCII/TCP

- Delta Electronics DVP

- Siemens S7 Communication

- Siemens PPI

- Mitsubishi MELSEC

- Allen-Bradley DF1

- 1-Wire

- ОWЕN

- Carel Easy

- User-defined protocols

«Multi-protocol» function: ability to work simultaneously with different protocols on the same physical RS-485 line.

Custom protocols: for non-standard or not supported devices, the user himself can add program code to send and receive protocol telegrams, using a handy scripting language Lua.

Data exchange optimization: there are possibilities of assigning different priorities for communication to get faster response and speed for specific data, limiting scan time, and using block reads for faster data exchange.

«Any-to-any protocol» gateway function: using the built-in scripting language, you can easily implement data exchange between different (with incompatible protocols) automation devices connected to WebHMI, like PLCs, remote I/O, etc.

Integration possibilities

Custom API: using API calls, WebHMI can directly exchange data with any business or user applications, other web-sites etc.

ModBus TCP Server: a group of tags can be accessed by external clients like SCADA system, PLC or another WebHMI, via Modbus TCP protocol

Automated control

User scripts: user can write functions in popular scripting language Lua, for implementing fairly complex algorithms of data processing, schedulers, logic control (similar to PLC) etc.

Notifications

SMS, Viber, Telegram

Network capabilities

Built-in router functions: routing, firewall, NAT, and other features allow you to integrate WebHMI in any network infrastructure without additional network equipment

Wi-Fi interface: can work simultaneously in different networks, as a client and as an access point, WPS mode is also supported

VPN support: simple implementation of remote access to the system, without use of dedicated static IP-addresses.

NTP server/client: time synchronization via NTP protocol

Built-in support for 3G modems. Modem re-initialization by disabling USB power is supported too.

Remote service access: user can operate the equipment connected to WebHMI using service and development tools, via a virtual COM port and Ethernet (using the possibility of forwarding traffic over the gateway)

Specifications

Platform

Ultra-compact, fanless

MIPS processor architecture, Embedded Linux

Storage

Industrial SD cards, up to 32GB

Interfaces

2 × Ethernet 100BASE-T,

RJ45 with galvanic isolation, ESD 3 kV

1 × WLAN 802.11 b/g/n (transmitter power 100 mW),

RP-SMA antenna connector

1 × RS-485, «Multi-protocol» mode, 250/921 Kbits/sec*, with galvanic isolation of 2500 V, ESD – 8 kV

1 × USB 2.0 — load capacity up to 500 mА, controlled power, ESD protection comp. IEC 61000–4–2 level 4: 15 kV (air discharge) — 8 kV (contact)

Additional ports: RS-232/422/485, M-bus, 1–Wire, etc. via USB converters

Modem support

3G, CDMA, GSM, EDGE

Input/output

2 × solid state relays (125mA, 24V)

Clock

- Real Time Clock with backup battery (CR3032)

- NTP client

- NTP server

Watchdog timers

Yes (system and communication)

Speed and performance

Configurable poll time (up to 5 ms)

Adjustable frequency of the data display in the web interface (up to 50 ms)

Power

Input: 24V (18…32V), 100-500mА

Built-in UPS (Li–Po battery, 7.4V 650mAh) for up to 2 hours work during power outages

Housing

ABS-plastic, mounting on DIN-profile

Protection

IP40

Dimensions (HxWxD)

101×35×120 mm.

Weight

300 gr.

Operating temperature range

0—50 ˚С

Standard compliance

CISPR 22:2007, CISPR 24:2008 (CISPR 24:1997, IDT), 4467–1:2005, IEC 61131-2:2006, 3626-97

Contents of package

- Packaging

- Interface connector

- Wi–Fi antenna

- Warranty card