Technical audit for pump stations

Description

The company which designs and services water pumps, decided to provide their potential customers advanced service of objective analysys for customer’s pumps operation mode, aiming to conclude if the upgrade or some improvement of the pump is required. The task was to get automatic recording tool of the pump’s efficiency and “pressure – flow” curve.

After such an analysys it is possible to choose better method of improving pump system efficiency, e.g. by changing its operating point using variable frequency drive, pump replacement etc.

The requirements for the audit tool were:

- High polling speed, signal processing (mean averages, efficiency calculation – hydro power to electric power ratio, displaying trends)

- interfaces to flow meters, electricity meters, and data acquisition devices using Modbus RTU protocol

- Remote (via internet) monitoring and configuration

- Logged data import into MS Excel, to calculate using defined procedure.

- Small size and mobility, all the electronics had to fit portable case.

Existing system drawbacks

- The existing system was outdated (had been in use more than 10 years)

- No remote access option

- Input signals set could not be changed, i.e. the setup was “static”. The more flexible system was needed.

The project setup after WebHMI application

The WebHMI features allowed to quickly solve the task of technical audit unit development:

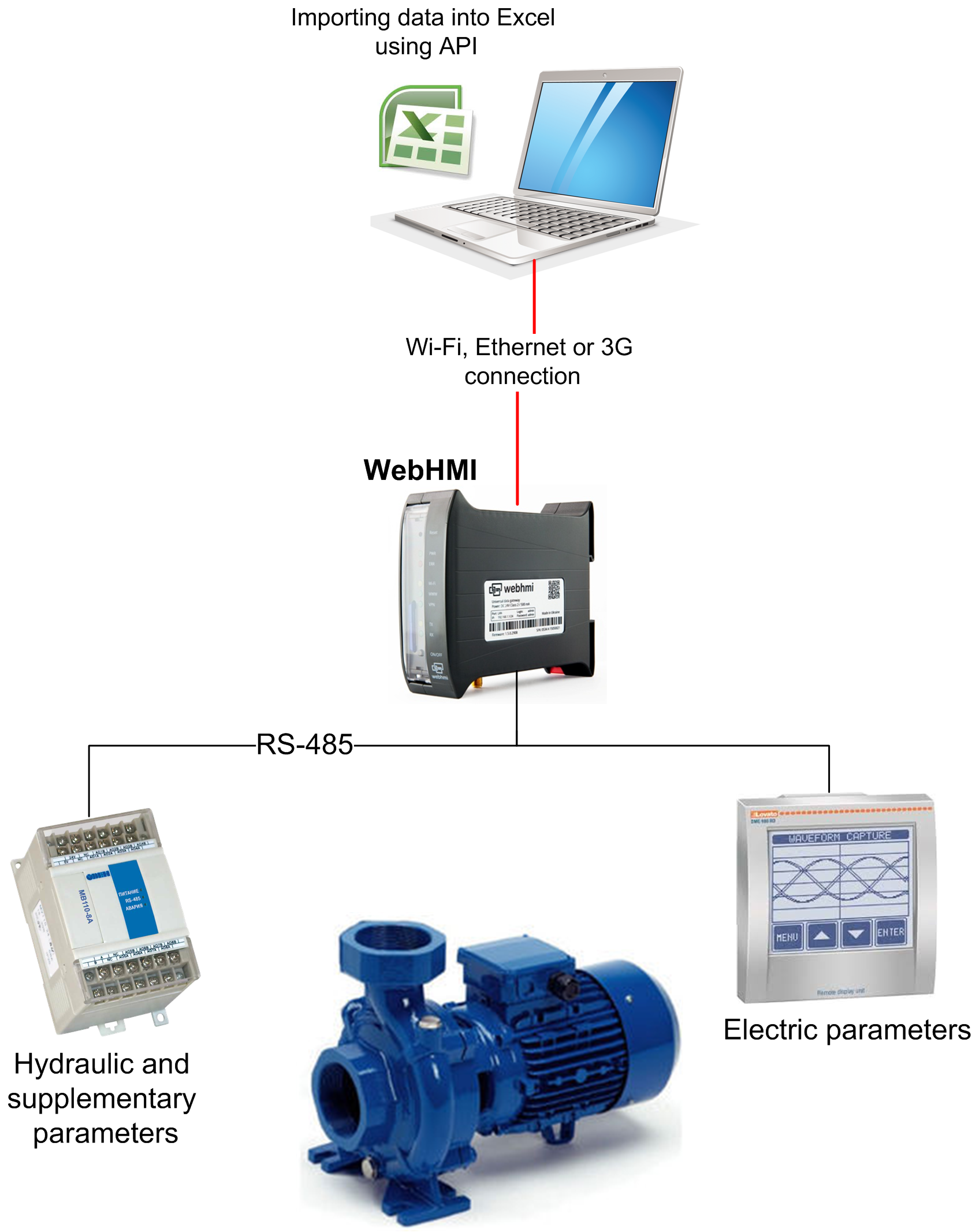

- Data acquisition devices was connected to WebHMI via RS-485.

- Visualization and data log system was configured (not programmed) for polling, logging and processs visualization in online mode.

- Scripts were useful for signal processing.

- Logged data were imported into *.xls file using API for further calculation procedure

- The remote access to the audit unit in the field was easily set up using 3G modem.

Advantages

- Fast development time, due to WebHMi featrues.

- Low expenses for the system

- Remote access via 3G modem using VPN connection

Secondary advantages the customer got also were:

- Embedded WebHMI online development environment provides the user with the audit unit flexiblility for similar tasks – not only for pump equipment, but for boiler rooms, building(power consumption audit), etc.