Conventional supervisory control systems generally require operator desktop computer or operator panel, fixed in the area where personnel works. Furthermore, it is a special device which is designed and configured to perform this specific task.

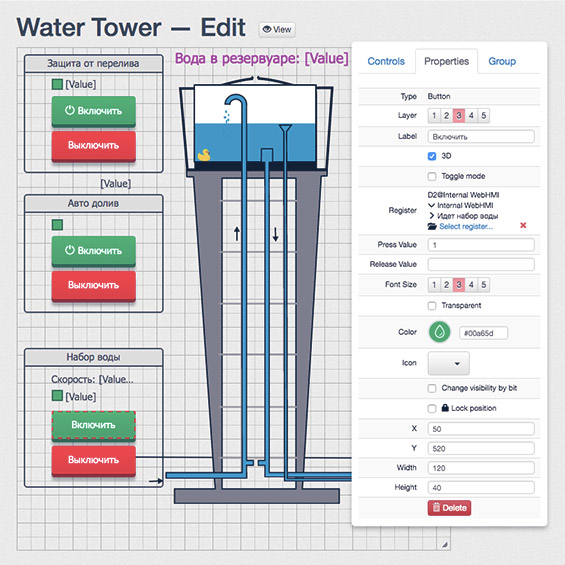

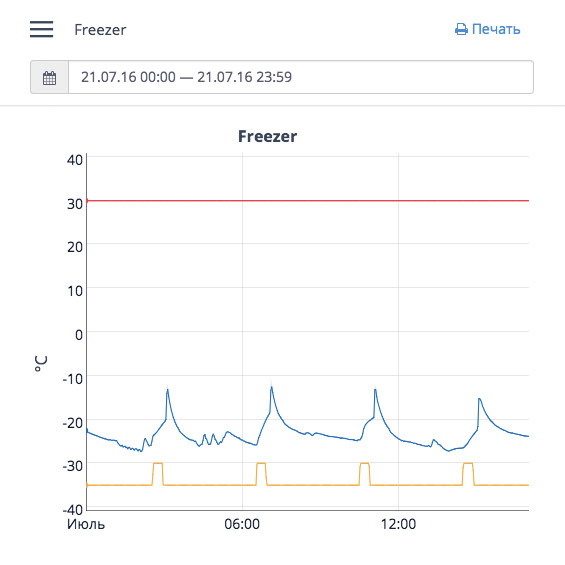

Using WebHMI, user is not limited of the used device and the location for access to the controlled equipment. This can be any stationary or portable computer, tablet, smartphone, connected via a local network or a wireless access point to WebHMI.

Multiple such devices can be used simultaneously if this is necessary. This adds flexibility and convenience of the control system.