Irrigation system monitoring

Description of the system

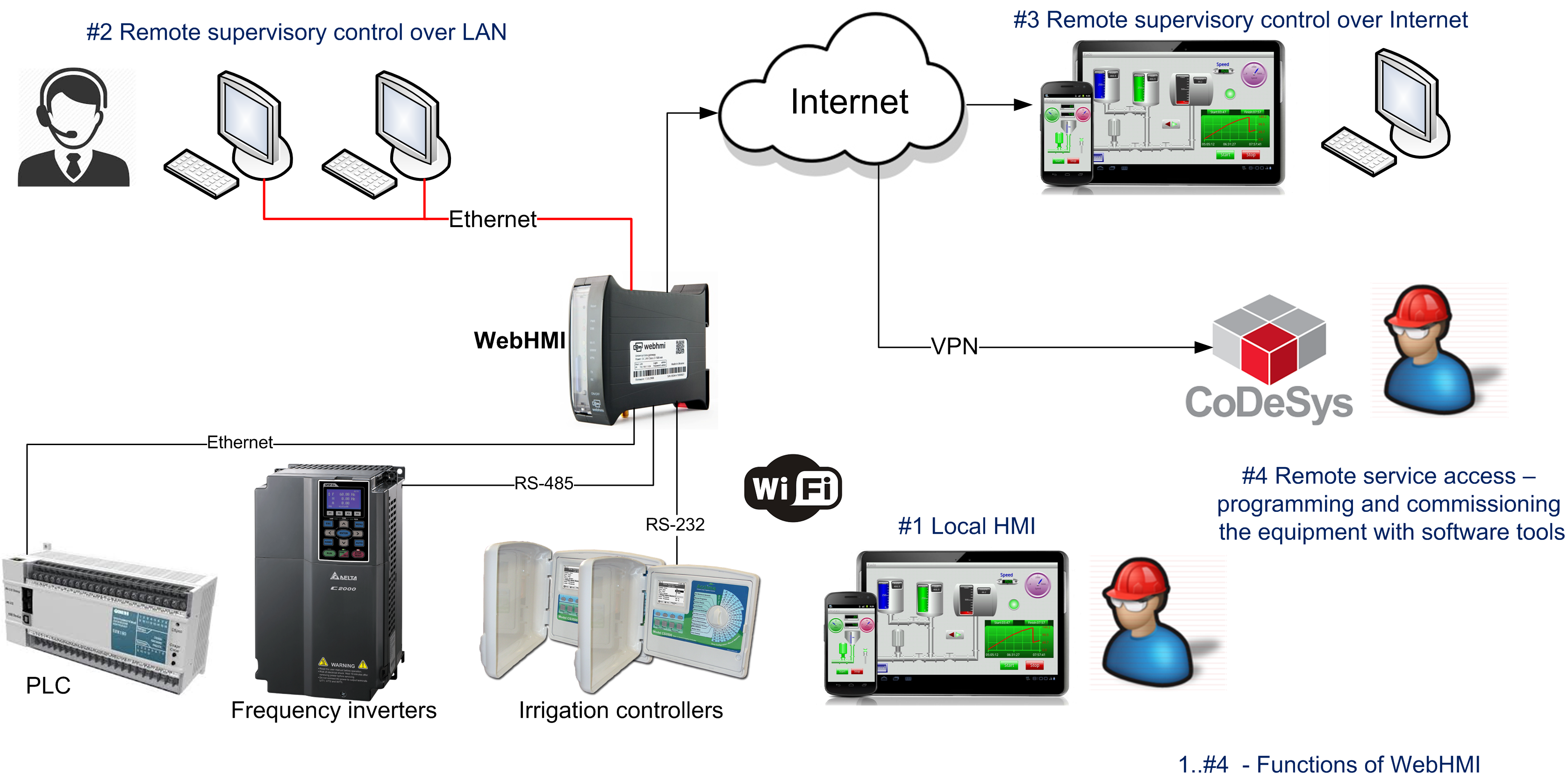

The company, which is engaged in the design, installation and maintenance of irrigation systems (including large stadiums, parks, hotel complexes, etc.), contacted us with a project to implement monitoring and diagnostics for important and remote sites. According to the idea, this system should provide independent access to the technological equipment for developers (without using of “remote desktops”, TeamViewer, etc., regardless of the operating personnel).

Project configuration before WebHMI application

Typical structure of the system in the example of a hotel complex includes two control cabinets for irrigation equipment with frequency converters and automation with the following automation facilities:

- PLC OWEN 160 – 2 pcs.

- SP270 panel OWEN 7 ” – 2 pcs.

- Acclima watering controller – 4 pcs.

- MasterSkada for one workplace

Obvious weaknesses of existing systems at the stage of monitoring implementation

- Problems with communication channels. Often such objects are removed from civilization, there is not always an opportunity to connect to the wired Internet, also, often owners do not give external access to their networks to outside companies for security reasons.

- The organization of a remote workstation for service access in SCADA requires the purchase of special modules for the existing server part, the purchase of another run-time SCADA license – systems for the remote workplace.

- Absence of the upper level, where the data from the objects arrives. If there are several objects, their monitoring becomes cumbersome and not an easy task.

- The facilities have already been commissioned and no one wants to interfere with the operation of the equipment.

- SCADA only controls the automation, it’s not enough to understand the cause of the malfunction. For diagnostics, it would be best to access the Acclima Irrigation Controller directly with its service utilities.

Project configuration after using WebHMI

WebHMI successfully combined the properties of the SCADA system – the creation of dashboards (mimic diagrams) for monitoring status and management, historical charts and trends, user scripts, automatic SMS notification and a ready integration platform with 3G support, VPN with the ability to easily organize remote service access to System (not only to the WebHMI project, but also to devices behind it – PLC, frequency drive, etc.).

These and other possibilities have led to the most effective use of WebHMI integration controllers at customer sites.

Additional benefits

The use of WebHMI allowed not only to efficiently accomplish the tasks (remote independent monitoring of the installation status), but also to optimize the automation structure for new watering systems implemented by the customer and save money by eliminating the 2 operator panels and the SCADA system from the specification. It’s also easier to work with the project – no need to program the operator panel separately and deploy the SCADA system, everything can be done with just one device – WebHMI. In the future, the customer also plans to abandon the PLC using by transferring all logic to WebHMI scripts.

Remote monitoring allowed the customer to reduce costs and improve system performance by reducing travel expenses, resource planning and rapid response to emergencies.

Thus, the only one device completely solves communication, visualization, control, monitoring and service access issues.